Close

Square Tube and Round Tube Features and Application

Square Tube and Round Tube Features and Application

Square tube

The square pipe is a kind of hollow square section light thin-wall steel tube, also known as steel refrigerated bending section. It is G235 hot rolled or cold rolled strip or coil as raw material, first by roll forming process and then high frequency welding made of square section shape size section steel. It has good comprehensive mechanical properties, weldability, cold, hot machining and corrosion resistance, with good low temperature toughness.

Performance of square tube

1. Plasticity is the ability of a metal material under load to produce plastic deformation (permanent deformation) without damage.

2. Hardness is the indicator to measure the hardness of metal materials. At present, the most commonly used method to measure hardness in production is the pressing hardness method, which is to use a certain geometry of the head under a certain load into the surface of the tested metal material, according to the degree of being pressed to determine its hardness value.

Commonly used methods include Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) and Vickers hardness (HV).

3. The strength, plasticity, and hardness discussed above are indicators of the mechanical properties of metals under static load. In fact, many machines parts work under cyclic loading, under which conditions they can become fatigued.

4. Impact toughness the load acting on the parts at a great speed is called impact load, and the ability of metal to resist damage under impact load is called impact toughness.

Strength refers to the resistance of a metal material to failure (excessive plastic deformation or fracture) under static charge. Due to the action of the load in the form of tension, compression, bending, shear, so the strength is also divided into tensile strength, compressive strength, flexural strength, shear strength and so on. There is always a certain relationship between all kinds of strength, generally more use tensile strength as the most basic strength pointer.

The application of the square tube is for construction, machinery manufacturing, steel construction projects, shipbuilding, solar power stents, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain wall, automobile chassis, airport, the boiler construction, highway railings, housing construction, pressure vessel, oil tank, bridge, power station equipment, lifting transportation machinery and other high load of welded structure, etc.

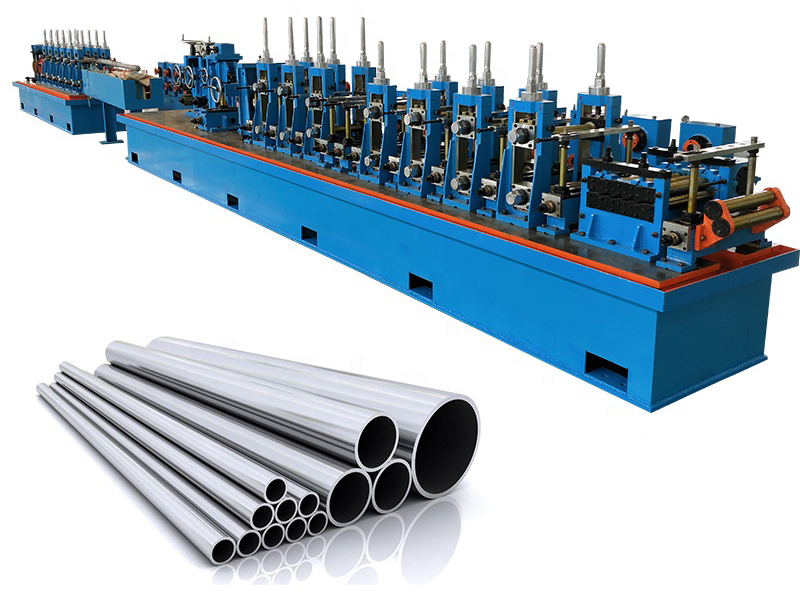

Round tube

Open at both ends and with a hollow concentric circular section, the length of which is larger than that of the surrounding steel. The specifications of the tubes are expressed in terms of external dimensions (such as outside diameter or side length) and inside diameter and wall thickness and range in size from small capillaries to large round tubes up to a few meters in diameter.

The circular pipe can be used for piping, thermal equipment, mechanical industry, petroleum geological drilling, container, chemical industry and special purpose. The common structural round steels vary according to their sizes and USES. The small ones are used for decorative members, assembled roof truss, supporting members, network truss and pipe trusses, etc. The large ones can be used for concrete-filled steel tubular columns in heavy steel workshops and large stadium pipe trusses, etc. Another main use of round steel is process piping, but there are generally special material and anti-corrosion requirements.

Tag: H-beam Production Line ; C Purlin Roll Forming Machine

Related Recommendations

C Z Purlin Roll Forming Machine

C Z Purlin Machine, also called fast change Steel Purlin Making Machine or C & Z Shape Interchangeable Rolling Machine, can be used to produce both C channel and Z channel with various sizes, in different thickness, and with punch on web and flange side

Lipped Channel Purlin Roll Forming Machine

The CZ Purlin Roll Forming Machine is used to produce both C and Z purline on one machine Adjust from one shape to the other, one operator o...

Novotek Purlin Roll Forming Machine Factory

We are the biggest cz purlin making machine factory in China, and is the only one who can manufacture the fully automatic purlin roll forming machine

Product Catalog

- C/Z Purlin Machine

- Fully Automatic CZ Purlin Roll Forming Machine

- Semi Automatic CZ Purlin Roll Forming Machine

- CZ Purlin Roll Forming Machine (400A)

- CZ Purlin Roll Forming Machine (400/4mm)

- Light Gauge Steel Framing Machine (100m/min)

- Pre-Cut CZ Purlin Machine

- Pre-Punch CZ Purlin Machine

- CZ Purlin Stacking Machine

- Stacking Machine (C Purlin)

- Steel Strapping Machine (Purlin/Pipe Packing Machine)

- U Purlin Machine (40m/min)

- U V L Channel Roll Forming Machine (65m/min)

- PGC/ PGU Purlin Roll Forming Machine

- Multi Profile Purlin Roll Forming Machine

- CZ Purlin Roll Forming Machine 320A

- Z Purlin Roll Forming Machine

- Hat Profile Roll Forming Machine

- Solar PV Support Roll Forming Machine

- Large High Speed Purlin Line

- High Speed CUZ Purlin Roll Forming Machine

- Full Automatic Stud Track Roll Forming Machine

- C Purlin Roll Forming Machine with Stacker (5mm)

- Non-stop Cutting C Purlin Roll Forming Machine

- CZU Purlin Roll Fomring Machine with Fly Cut

- Coil Slitting Machine (1-3mm)

- Completely Automatic CU Purlin Roll Forming Machine

- Fly Punch & Fly Cut Purlin Machine

- Box Beam Roll Forming Machine

- Beam Profile Roll Forming Machine

- Roll Forming Machine

- Deck Sheet Roll Forming Machine

- Roof Sheet Roll Forming Machine (30m/min)

- Corrugated Sheet Roll Forming Machine (35m/min)

- Roof Sheet Roll Forming Machine with Stacker

- Double Layer Roll Forming Machine

- Three Layers Roll Forming Machine

- Guardrail Roll Forming Machine

- Standing Seam Roll Forming Machine

- High Speed Roofing Panel Roll Forming Machine

- Downspout Roll Forming Machine

- Roof Sheet Crimping Curving Machine

- Mesh Welding Machine

- Metal Floor Decking Roll Forming Machine

- K-Span Roll Forming Machine

- H Beam Welding Machine

- Cable Tray Roll Forming Machine

- Hydraulic Folding Machine

- Barrel Corrugated Machine

- Roof Panel Roll Forming Machine

- Stud Track Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Door Frame Roll Forming Machine

- PV Support Bracket Roll Forming Machine

- Mini Coil Slitting Machine

- EPS Sandwich Panel Machine

- PU Sandwich panel machine

- Rockwool Sandwich Panel Machine

- Sandwich Panel Band Saw Cutting Machine