二層ロール成形機

NOVOTEKが設計した二層成形機の上層機と下層機は、アンコイラー、機械ベース、メインモーター、電気キャビネットなどを共有しており、1台の機械で2種類の異なるプロファイルを成形できます。これにより、機械投資コストを削減できるだけでなく、工場の省スペース化にも貢献します。

このタイプの機械で製造されるプロファイルには、屋根シート、波形シート、壁パネル、施釉タイルなどがあります。

ロール成形機の主機

1. 二重層構造を採用しており、上層は波形プロファイルを生成し、下層は台形プロファイルを生成します。

2. ロールスタンド、上層:16ステーション、材料供給ローラー、メイン成形ローラーを含む。下層16ステーション、材料供給ローラー、メイン成形ローラーを含む。

3.主モーター出力:7.5KW、サイクロイドコーンプーリー減速機、チェーン伝動を採用

4.ローラーの材質:45#スチール、クロームメッキ

5. ローラーはCNC工作機械で仕上げ加工され、表面は研磨仕上げが施され、粗さは0.05mmです。

二層ロール成形機のカッター

1. ポストカットを採用し、長さに合わせて自動的にカット

2.カッター材質:GCr12、焼入れ、硬度はHRC58-62

3. 切断精度:長さ10m±2mm

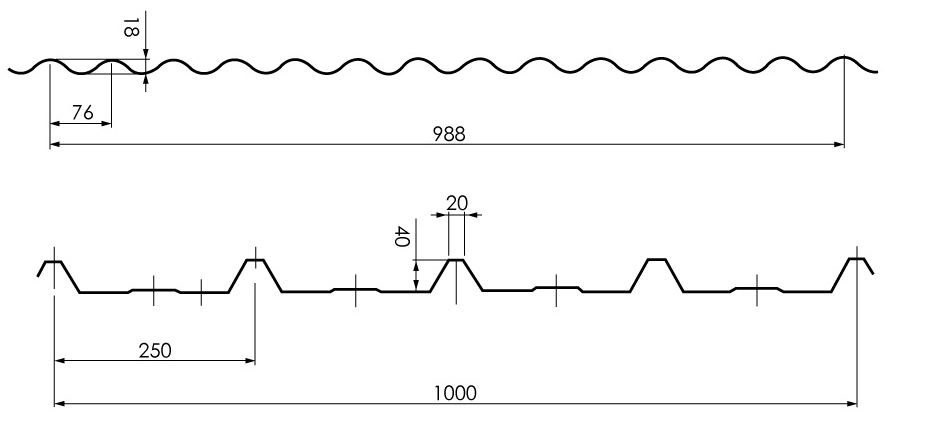

2層プロファイルの標準プロファイル図面

仕様

二層ロール成形機の技術仕様

アイテム | パラメーター |

コイル厚(mm) | 0.4~0.8 |

最高速度(メートル/分) | 0~12m/分 |

プロファイル タイプ | オーダーメイド |

ロールスタンド | 18/20 |

主力 (Kw) | 7.5 |

メインシャフト (mm) | φ70 |

カッター材 | Cr12 |

切削精度 | 10±2mm |

油圧ステーション出力 (Kw) | 5.5 |

制御システム | シーケンサ |