Roof Sheet Roll Forming Machine

Steel roof tile sheets are the new substitutes for traditional clayey, concrete tiles. They are popular because of their low cost, short building period; re-cycle use, and elegant appearance. They can be used as the roof of villas, luxury houses, theatres, exhibition centers.

Main Machine of Roof Sheet Machine

1. Roll stand: 16 stations, it includes leveling rollers, main forming rollers

2. Main motor power: 5.5KW, it adopts cycloid cone pulley reducer, chain transmission

3. Material of the roller: 45# high grade steel, chromeplate

4. The roller processed by CNC machine with finish machining. The surface adopt finished polishing, the roughness is 0.05mm

5. Material of the main shaft: 45# forged steel with heat treatment

6. The diameter of the main shaft: Φ70mm

7. Machine frame: welding by 350 x 175mm H shape steel, by using carbon dioxide gas arc welding. The surface used shot blasting treatment.

Electric Control System of Roof Sheet Tile Machine

1. Control system: PLC (OMRON or MITSUBISHI brand)

2. Operation platform: touch screen and press button

3. Main motor: AC frequency conversion electric motor

4. Inverter (HOLIP brand), Touch panel (WEINVIEW or MITSUBISHI brand), low voltage electric parts (CHINT brand)

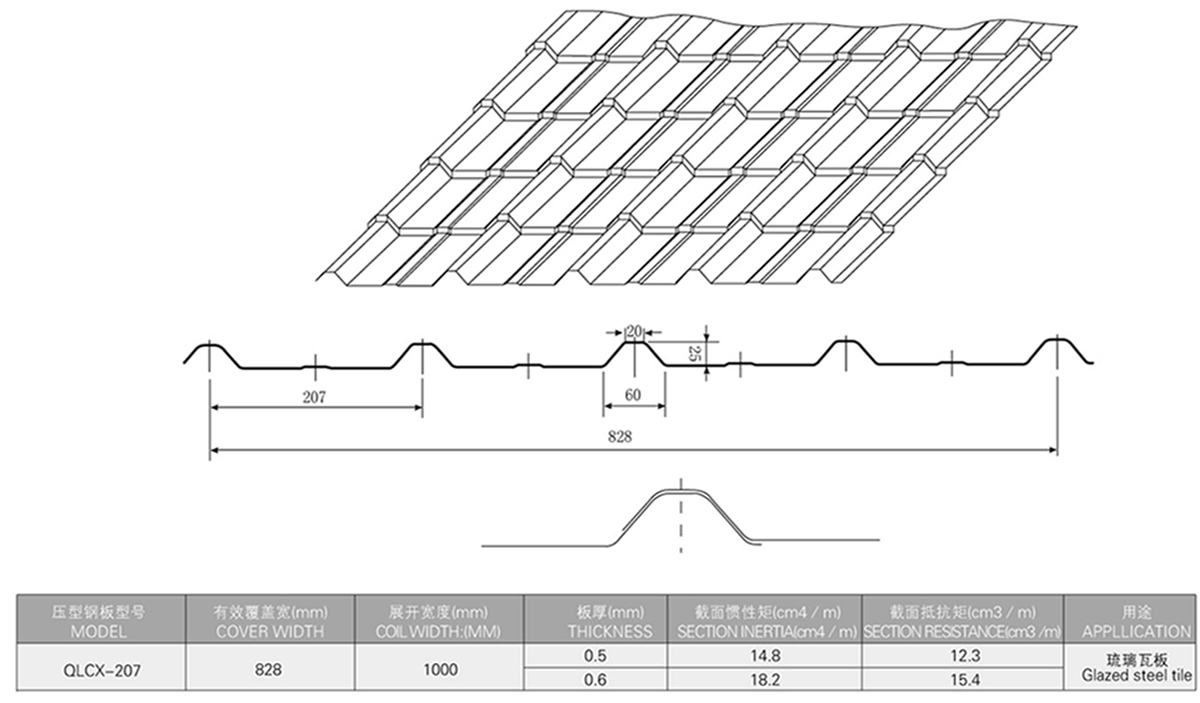

Typical Profile Drawing of Roof Sheet Tile Machine

Especificación

| Artículo | Parámetros |

| Espesor de la bobina (mm) | 0.3-0.7 |

| Soporte rodante | dieciséis |

| Potencia principal (Kw) | 5.5 |

| Eje principal (mm) | Ø70 |

| material de corte | cr12 |

| Precisión de corte | 10±2mm |

| Potencia central hidráulica (Kw) | 4 |

| Sistema de control | SOCIEDAD ANÓNIMA |

| Dimensión de la máquina principal (mm) | 8500x1000x80 |